High-end standard mold shoe

NL-Custom exclusively developed shoe last for sports

Features of our lasts

1. Through 3D scanning comparison, forefoot and the lower heel will be even fitter that strengthen the overall power output.

2. While optimizing the application of force on sole, we make the balance control on the ground more easily.

3. The necking support on the ankle bone can enhance the stability for speed-turning around corners.

Production Features

1. Under a complexone-piece craft, the high-end standard mold shoes are made with carbon fiber wrapping the doubler, which makes the overall covering and durability are unparalleled to common lasting standard mold shoes.

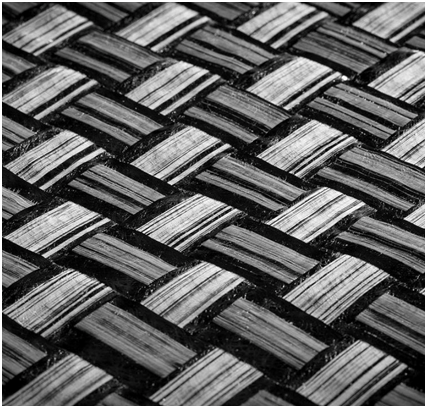

2. NL-Custom's carbon fiber molding adopts exclusive CFGS (Carbon fiber geometric stacking) technology, which can achieve the optimal weight and strength ratio.

3. The U-shaped stiffener ribs on the forefoot can reduce the loss of force when the output power approaches the peak.

4. The figure-eight-curve foot spikes spacer, which were developed on our own, can make the force on the left and right sides more evenly transmitted.

5. Anextra silicone spacer is put on the top of the tongue to reduce friction on instep.

NL-Custom Procedure and features of foot model shoes

Mocking up

NL-Custom adopts polymer resin bandage for mocking up. Unlike traditional mocking up procedure with plaster bandage and algin, polymer resin bandage can perfectly represent shape of soles. Apart from that, the problem of size deviation caused by algin inflation can be avoided with our procedure, which is the perfect mocking up solution.

Trimming plaster foot model

After taking out the whole plaster model, we will conduct trimming, the most crucial part. To turn the original foot model into shoe last model, plaster trimming can be the key to fail or success for making custom boots. Technique of trimming is similar to sculpture that takes years of experience to become professional. Those international top craftsmen of foot model shoes in this industry are all retired speed skaters, and only these people understand what a speed skater need.

Preceding operation and manufacture of lining

Different kinds of preceding operation and modeling production will apply on each pairs of foot model shoes from NL-custom. In consider with comfort and forefoot tightness, we apply production with shaped piece or carbon fiber wrapping doubler. This is the exclusive process from NL-Custom, also the best way for making the most fitting boots to our customers.

Carbon fiber and fiber formation

NL-Custom adopt the exclusive CFGS(Carbon fiber geometric stacking) technique to proceed vacuuming formation to cover carbon fiber. The material of our foot model shoes is made from carbon fiber under TeXtreme production. This kind of carbon fiber is the ultimate choice as a long-lasting while extremely light material, which is the preferred one for most deluxe carbon fiber equipment. The carbon fiber production from TeXtreme is compared to the Patek Philippe of boutique watches by international experts.

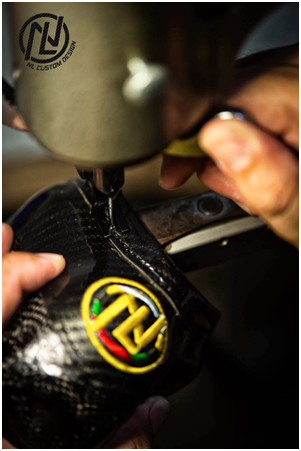

Leather Selection and Sewing Formation

After series of production procedure, the last step is to stick and stitch all the leather together. NL-Custom custom boots apply genuine leather made in Italy. With multiple leather styles and our online color matching system, you can preview how your custom boots will look like in the end as you operate the system.